Pad flanges, also commonly referred to as studding outlets, are specialized industrial components designed to provide connection points on vessels, tanks, and pipes with minimal projection . Unlike standard pipe flanges that connect two pipe ends, a pad flange is typically welded to the shell or head of a vessel to serve as a mounting point for equipment like sight glasses, level gauges, and flow indicators. Understanding pad flange dimensions is critical for engineers, designers, and maintenance personnel to ensure proper selection, leak-free performance, and system integrity.

This comprehensive guide provides detailed dimensional data, explains key design considerations, and answers frequently asked questions to help you master the technical specifications of these essential components.

Table of Contents

Understanding Pad Flange Types and Applications

Pad flanges are versatile components used across various industries, including chemical processing, oil and gas, power generation, and pharmaceutical manufacturing. Their primary advantage is minimizing the projection of equipment both inside and outside a vessel, which is crucial for space-constrained applications and for maintaining efficient flow dynamics.

Common Mounting Types:

- Flat Bottom: The most common type, designed for mounting on flat surfaces or where internal contouring is not required.

- Shell or Head Mount: Contoured to match the curvature of a vessel’s cylindrical shell or spherical head, ensuring a flush fit and a strong weld.

- Tangential Mount: Offset from the centerline, this type is used in specific configurations where space or internal components prevent central mounting. It is the least common and lacks symmetry.

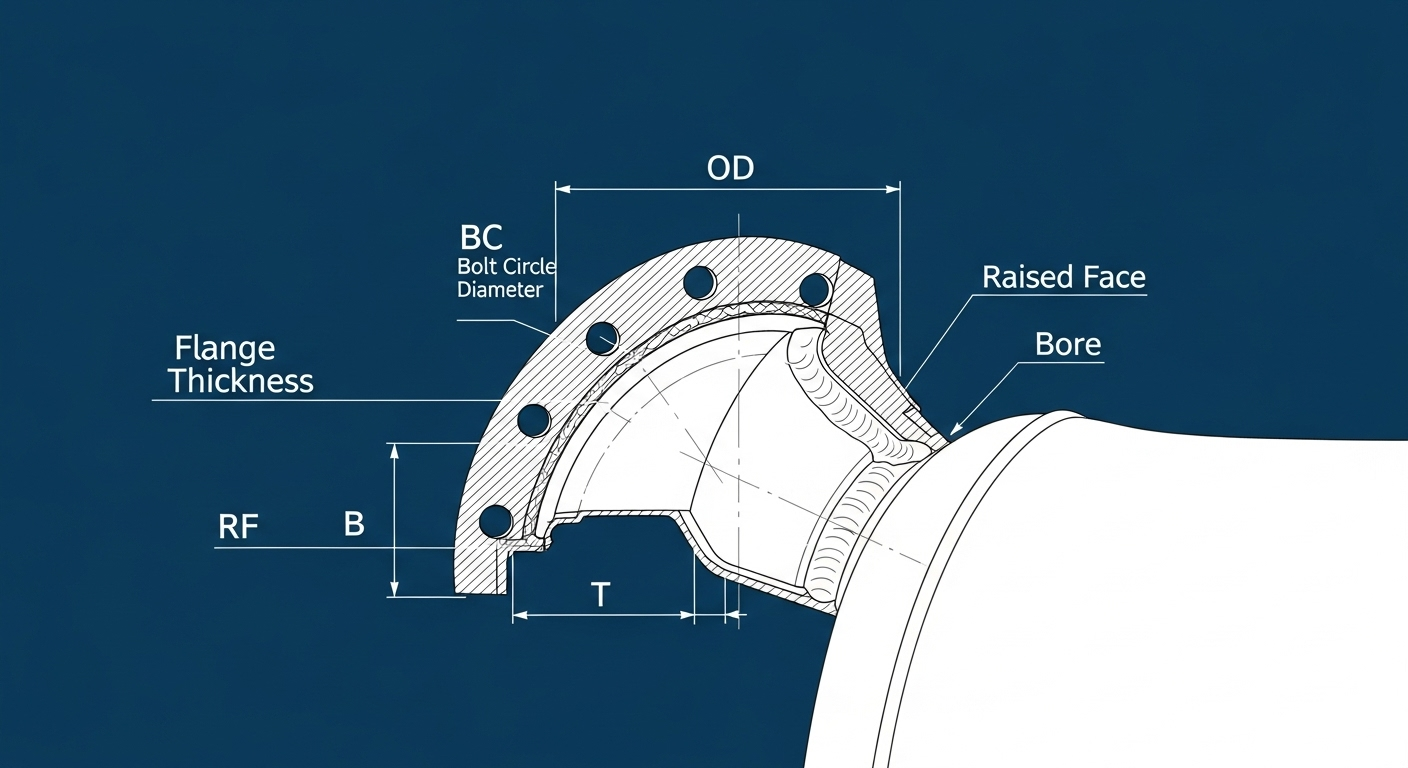

Key Pad Flange Dimensions and Terminology

To correctly specify and install a pad flange, you must understand its critical dimensional parameters. These dimensions are standardized under ANSI/ASME B16.5 for different pressure classes.

Table: Key Dimensional Terminology for Pad Flanges

| Dimension | Symbol | Description | Importance |

|---|---|---|---|

| Bore | B | The inner diameter of the flange opening, matching the nominal pipe size (NPS). | Determines flow capacity and must match the connecting equipment. |

| Outside Diameter | O | The overall diameter of the flange body. | Determines the spatial envelope and required clearance. |

| Flange Thickness | T | The minimum thickness of the flange body. | Critical for structural strength and pressure containment; designed per ASME codes. |

| Raised Face Diameter | R | The diameter of the raised sealing surface. | Accommodates a gasket for a leak-free connection. |

| Bolt Circle Diameter | C | The diameter of the circle through the centers of the bolt holes. | Essential for proper alignment with a mating flange or equipment. |

| Number of Bolt Holes | V | The quantity of bolts required for the connection. | Affects the clamping force and sealing integrity. |

| Bolt Hole Diameter | U | The diameter of individual bolt holes. | Must match the bolt size for a secure fit. |

ANSI/ASME B16.5 Class 150 Pad Flange Dimensions

The following table provides standard dimensions for Class 150 studding outlets or pad flanges, which are rated for a maximum pressure of 150 PSI and are among the most commonly used in industrial applications .

Table: Class 150 Pad Flange Dimensions (Standard Sizes)

| Nominal Pipe Size (NPS) | Outside Diameter (O) | Flange Thickness (T) | Raised Face Diameter (R) | Bolt Circle Diameter (C) | No. of Bolt Holes | Bolt Hole Diameter (U) | Tap Size |

|---|---|---|---|---|---|---|---|

| 1/2″ | 3.50 inches | 1.25 inches | 1.38 inches | 2.38 inches | 4 | 27/64 inch | 1/2″-13 |

| 3/4″ | 3.88 inches | 1.25 inches | 1.69 inches | 2.75 inches | 4 | 27/64 inch | 1/2″-13 |

| 1″ | 4.25 inches | 1.25 inches | 2.00 inches | 3.12 inches | 4 | 27/64 inch | 1/2″-13 |

| 1-1/4″ | 4.62 inches | 1.25 inches | 2.50 inches | 3.50 inches | 4 | 27/64 inch | 1/2″-13 |

| 1-1/2″ | 5.00 inches | 1.25 inches | 2.88 inches | 3.88 inches | 4 | 27/64 inch | 1/2″-13 |

| 2″ | 6.00 inches | 1.50 inches | 3.62 inches | 4.75 inches | 4 | 17/32 inch | 5/8″-11 |

| 2-1/2″ | 7.00 inches | 1.50 inches | 4.12 inches | 5.50 inches | 4 | 17/32 inch | 5/8″-11 |

| 3″ | 7.50 inches | 1.50 inches | 5.00 inches | 6.00 inches | 4 | 17/32 inch | 5/8″-11 |

| 4″ | 9.00 inches | 1.50 inches | 6.19 inches | 7.50 inches | 8 | 17/32 inch | 5/8″-11 |

| 6″ | 11.00 inches | 1.75 inches | 8.50 inches | 9.50 inches | 8 | 21/32 inch | 3/4″-10 |

| 8″ | 13.50 inches | 1.75 inches | 10.62 inches | 11.75 inches | 8 | 21/32 inch | 3/4″-10 |

| 12″ | 19.00 inches | 1.81 inches | 15.00 inches | 17.00 inches | 12 | 49/64 inch | 7/8″-9 |

Important Notes on Class 150 Dimensions:

- Raised Face: For Class 150, the height of the raised face is approximately 1/16 inch and is included in the listed thickness ‘T’.

- Thickness (‘T’): The values shown are the minimum required per ASME Section VIII Division I for thread engagement. The actual thickness for a specific application must be analyzed based on design pressure, temperature, and loadings.

- Materials: These flanges are commonly made from SA-105 carbon steel, but are also available in stainless steel, alloy steel, and other materials to suit service conditions.

Key Standards and Specifications:

- ASME B16.5: Defines dimensions, tolerances, materials, and pressure-temperature ratings for flanges from NPS ½” to 24″.

- ASME Section VIII, Division 1: Governs the design and fabrication of pressure vessels, including the rules for pad flange thickness and attachment.

- Material Specifications: Common material standards include ASTM A105 for carbon steel, ASTM A182 for stainless and alloy steels, and various other ASTM specifications for exotic materials.

- Face Types: Pad flanges are available with different facing finishes, including Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ), with RF being the most common for Class 150.

Installation and Dimensional Considerations

Contoured Bottoms

While standard pad flanges come with a flat bottom, they can be furnished with a contoured bottom to fit the outside or inside diameter of shells, heads, or cones. This contouring ensures a flush fit, which is crucial for a strong weld and for minimizing turbulence or material buildup in the vessel. The tolerance for this contouring is typically in accordance with ASME Section VIII, Division 1.

Thickness Requirements

It is vital to understand that the standard thickness ‘T’ is suitable for certain attachment styles. For “through-type” installations where the pad flange is inserted into a hole in the vessel, the thickness often needs to be increased to provide sufficient material under the threaded holes, as required by ASME Section VIII, Division 1, paragraph UG-43(d). Each application should be individually analyzed to determine the proper thickness.

FAQs – Frequently Asked Questions

1. What is the difference between a pad flange and a standard pipe flange?

A standard pipe flange connects two sections of pipe. A pad flange (or studding outlet) is designed to be welded directly to a vessel, tank, or pipe wall to create a nozzle for attaching instruments or other equipment with minimal projection.

2. What does “Class 150” mean for a pad flange?

Class 150 indicates the pressure rating. A Class 150 pad flange is designed to handle a maximum pressure of 150 PSI at a corresponding reference temperature. The dimensions, especially thickness and bolting, are engineered to maintain a seal at this pressure.

3. Are pad flange dimensions standardized?

Yes, standard pad flanges from ½” to 24″ follow ANSI/ASME B16.5 dimensional standards. This ensures compatibility with other flanged components like valves and fittings from different manufacturers.

4. Can I get a pad flange with a bore size different from the nominal size?

Yes. While the standard bore matches the nominal pipe size, manufacturers can often furnish pad flanges with special bores (e.g., Schedule 40, 80, or custom sizes) upon request.

5. How do I choose the right material for a pad flange?

Material selection depends on the service environment. Carbon steel (ASTM A105) is common for general use. Stainless steel (ASTM A182 F304/F316) is chosen for corrosive environments, and alloy steels are used for high-temperature service.

6. What are the different mounting types for pad flanges?

The three main types are Flat Bottom (for flat surfaces), Shell or Head Mount (contoured for cylindrical/spherical vessels), and Tangential Mount (offset from the centerline).

7. Why is the thickness ‘T’ a critical dimension?

The thickness is calculated to ensure the flange has sufficient strength to withstand internal pressure and external loads without failing. Using a flange with insufficient thickness for the application can lead to leaks or catastrophic failure.

Conclusion

Understanding pad flange dimensions is fundamental to selecting the correct component for your application. By referencing the provided ANSI/ASME B16.5 Class 150 dimensional chart and understanding the key terminology, standards, and design considerations, engineers and specifiers can ensure a safe, reliable, and leak-free connection. Always remember to consider the specific operating conditions, including pressure, temperature, and the nature of the fluid, and consult with the flange manufacturer or a qualified engineer when dealing with non-standard or critical applications.

For all your Puddle Flange requirements, consult with reputable manufacturers and suppliers like Texas Flange, who can provide the right flange solutions tailored to your application’s demands.